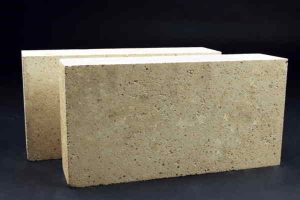

Zirconia corundum refractory brick is a white solid formed by melting alumina powder with zirconia sand containing 65% zirconia and 34% silica in an electric melting furnace and then injecting it into the model for cooling.

Its petrographic structure consists of corundum and zircon plagioclase copolymer and glass phase. According to the manufacturing process area, zirconium corundum bricks can be divided into two kinds AZS fused cast bricks and AZS fired bricks.AZS stands for Al2O3, ZrO2, and SiO2 respectively.

There are more types of such products, and the classification is named according to the ZrO2 content in the products, and there are common fused cast zirconium corundum bricks such as No.33 and No.40.

There are Five Kinds of Raw Materials Used in Zirconium Corundum Refractory Bricks:

Alumina, zirconia sand, zirconia-rich sand, soda ash, and borax.

1. The introduction of alumina is generally used in industrial alumina, the production requirements of its water content should be less than 0.3%, burn loss is well less than 0.15%, and a ton of AZS-33 electrofused bricks need about 0.62 tons of alumina.

2. Zirconia sand mainly leads to the staining of AZS products, causing coarse crystal trachoma, and also affects cracking, so its content should be less than 0.2%, affecting the cracking of castings during cooling, in addition, it also affects the oxidation process of products, so its content should be limited to less than 0.2%, and one ton of AZS-33 electrofused brick needs about 0.65 zirconia sand.

3. Zirconium-rich sand, also known as desilicified zirconium, all the silica in AZS comes from zirconite, and the shortage is supplemented by zirconium-rich sand.

4. Soda ash is introduced as sodium oxide, which is used as a flux for AZS brick and is generally used as a secondary product.

5. Borax is also used as a flux for AZS brick, one ton of AZS-33 electrofused brick needs about 20kg of borax.

Ring Masonry Method Of Electrofused Zirconium Corundum Brick

Since the field processing of electrofused zirconium corundum bricks is difficult and the processing accuracy of the product is also lacking, we think it is not appropriate to use staggered rows of masonry, so the method of ring masonry is used instead.

In the operation of the electrofusion brick manufacturer directly in the pre-row, and further finishing, to ensure that the size of each brick meets the requirements (error ≤ ± 1mm) at the same time, each ring can be a precision fit, smooth transition.

At the same time, each ring of brick is required to be perpendicular to its column edge, to ensure that no edge run in masonry, reducing the brick seam.

After the pre-arrangement acceptance, the bricks will be numbered and packed for shipment. The method of dry masonry does not require other binders.

Characteristics of Zirconium Corundum Refractory Bricks

1. High Temperature Resistance

Zirconium corundum refractory bricks exhibit exceptional resistance to high temperatures. They can withstand temperatures above 2000°C (3632°F) without significant degradation. This characteristic makes them suitable for applications in industries such as steelmaking, glass manufacturing, and petrochemical processing, where extreme heat is involved.

2. Excellent Thermal Shock Resistance

One of the outstanding features of zirconium corundum refractory bricks is their excellent thermal shock resistance. They can endure rapid temperature changes without cracking or spalling. This property is crucial in environments where the temperature fluctuates rapidly, such as in furnaces and kilns. The refractory bricks ensure the structural integrity of the lining, prolonging their lifespan.

3. Superior Chemical Stability

Zirconium corundum refractory bricks possess superior chemical stability, making them highly resistant to acidic and alkaline environments. They do not easily react with molten metals, slags, or corrosive gases. This characteristic is essential in industries where aggressive chemicals are present, such as the chemical and metallurgical industries.

4. Low Thermal Conductivity

The low thermal conductivity of zirconium corundum refractory bricks is another notable characteristic. It means that these bricks have excellent insulation properties, minimizing heat transfer through the refractory lining. This property helps to reduce energy consumption and maintain a stable temperature within the industrial process. Consequently, it improves efficiency and reduces operational costs.

5. High Mechanical Strength

Zirconium corundum refractory bricks exhibit high mechanical strength, enabling them to withstand the mechanical stresses and loads encountered in various applications. This strength is crucial for maintaining the structural integrity of the lining, especially in industries with frequent thermal cycling or mechanical movements.

6. Abrasion Resistance

These refractory bricks also possess excellent abrasion resistance. They can withstand the erosive forces caused by solid particles or abrasive materials. This characteristic is particularly advantageous in industries such as cement production and coal-fired power plants, where the refractory lining is subjected to abrasive wear.

7. Good Dimensional Stability

Zirconium corundum refractory bricks demonstrate good dimensional stability, meaning they maintain their shape and size even under extreme conditions. This property is important for ensuring a precise and consistent lining, as any dimensional changes can lead to inefficiencies or even failure of the refractory structure.

8. Easy Installation and Maintenance

Due to their favorable physical properties, zirconium corundum refractory bricks are relatively easy to install and maintain. They can be shaped, cut, and installed with ease, reducing the time and effort required for the lining process.

9. Versatile Applications

Zirconium corundum refractory bricks find versatile applications in various industries. Some common applications include:

Steelmaking: These bricks are used in steel ladles, tundishes, and other high-temperature zones of steelmaking processes.

Glass Manufacturing: They are employed in glass melting furnaces, where high temperatures and chemical resistance are required.

Petrochemical Processing: Refractory bricks are utilized in reactors, reformers, and other equipment involved in petrochemical processes.

Incinerators: Zirconium corundum bricks are suitable for lining incinerators due to their high temperature and chemical resistance.

Non-ferrous Metal Processing: They are used in the smelting and refining of non-ferrous metals like copper, aluminum, and nickel.

Cement Industry: These bricks are employed in rotary kilns and other high-temperature zones in cement production.

Power Generation: They find applications in coal-fired power plants and waste-to-energy facilities.

Conclusion

Zirconium corundum refractory bricks are a remarkable material with exceptional characteristics that make them highly desirable for applications in extreme conditions. Their high-temperature resistance, thermal shock resistance, chemical stability, low thermal conductivity, mechanical strength, and abrasion resistance make them suitable for various industries. These bricks provide reliable and durable solutions from steelmaking to glass manufacturing and petrochemical processing. With their easy installation and maintenance, zirconium corundum refractory bricks are a preferred choice for demanding industrial environments.