ما هو الطوب الحراري من كربيد السيليكون؟?

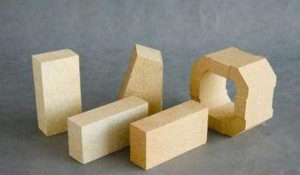

Silicon carbide refractory bricks are special refractory materials produced from silicon carbide (كربيد كربيد). لديها مقاومة جيدة للتآكل والتآكل, قوة درجات الحرارة العالية, الموصلية الحرارية العالية, small linear wedge expansion coefficient, ومقاومة جيدة للصدمات الحرارية. Silicon carbide refractory bricks can be classified according to the content of SiC, and the type of binding phase.

![]()

What Are The Types Of Silicon Carbide Refractory Bricks?

The performance of refractory bricks depends largely on the condition of the binding phase. According to the binding phase of silicon carbide refractory bricks can be divided into oxide binding – to aluminum silicate, silica as the binding phase. Nitride bonding – silicon nitride (Si3N4), silicon oxynitride (Si2ON2), or selon as the binding phase. Recrystallization – direct bonding between silicon carbide particles using recrystallization. Semi-silicon carbide refractory bricks can be further classified into various types, such as clinker silicon carbide refractory bricks + high alumina silicon carbide refractory bricks, zircon silicon carbide refractory bricks, silicon carbide graphite refractory bricks, mullite silicon carbide refractory bricks and corundum silicon carbide refractory bricks.

Application Of Silicon Carbide Brick

In iron and steel smelting, it can be used for steel barrel lining, water mouth, plug head, blast furnace bottom, furnace belly, iron out of the trough, converter and electric furnace outlet, heating furnace without water cooling slide, إلخ. In non-ferrous metal (zinc, actinium, الألومنيوم, إلخ.) smelting, numerous distillers, distillation tower tray, electrolysis tank side wall, molten metal pipeline, suction pump, and melting metal crucible. Silicate industry, it is used in large quantities as a variety of kilns and flame insulation materials, such as muffle furnace lining and sagger. في الصناعة الكيميائية, it is used in oil and gas generators, organic waste calcining furnaces, petroleum vaporizers, وأفران إزالة الكبريت. فضلاً عن ذلك, in space technology can be used as rocket nozzle and high-temperature gas turbine blades.

![]()

The Use Of Silicon Carbide

1. Abrasives – mainly because of the high hardness, chemical stability, and certain toughness of silicon carbide, silicon carbide can be used in the manufacture of cemented abrasives, coated abrasives, and free grinding, to process the glass, سيراميك, stone, cast iron and some non-ferrous metals, cemented carbide, titanium alloys, high-speed steel cutting tools and wheels and so on.

2. Refractories and corrosion-resistant materials – mainly because of the high melting point of silicon carbide (decomposition), chemical inertia, and resistance to thermal vibration, silicon carbide can be used for abrasives, ceramic products firing kiln with the shed and sagger, zinc refining industry, vertical distillation furnace with silicon carbide bricks, aluminum electrolysis tank lining, البوتقات, small pieces of furnace materials, such as a variety of silicon-carbide ceramic products.

3. Chemical use – because silicon carbide can be decomposed in molten steel and steel water and oxygen, metal oxides react to generate carbon monoxide and silicon slag. So it can be used as a smelting iron and steel purification agent, إنه, used as a steelmaking deoxidizer and cast iron organization improvement agent. This generally uses low-purity silicon carbide to reduce costs. At the same time can also be used as a raw material for the manufacture of silicon tetrachloride.

4. Electrical applications – as a heating element, non-linear resistance elements, and high semiconductor materials. Heating elements such as silicon-carbon rods (for 1100 ~ 1500 ℃ work of various electric furnaces), non-linear resistance elements, and various types of lightning valves.

5. Other formulated into far-infrared radiation coating or made of silicon carbide silicon plate with far-infrared radiation dryer.

ك professional refractory manufacturer with good quality and low price, PER Refractory adopts automatic production processes and equipment, and introduces advanced management and quality control system. We ensure that each batch of refractories can meet the requirements of users, and the quality of silicon carbide refractory bricks is worthy of your trust.