As we all know, bricks have been used for centuries as a building material due to their durability, Stärke, and aesthetic appeal.

Jedoch, not all bricks are created equal. There are various types of bricks available in the market, and each one has its own unique properties and characteristics that make it suitable for specific applications.

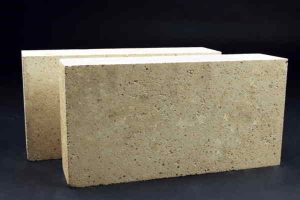

In this article, PER Refractory will discuss the difference between clay bricks and refractory bricks, two commonly used types of bricks.

1. Introduction

Bricks are an essential building material and have been used for construction purposes for thousands of years.

They are made by molding clay or other materials into the desired shape and then firing them in a kiln.

Clay bricks and refractory bricks are two types of bricks that are commonly used in construction and other applications.

While they may look similar, they have significant differences in terms of their composition, manufacturing process, Eigenschaften, and applications.

2. What are Clay Bricks?

2.1 Composition

Clay bricks are made from natural clay and shale that is formed into a rectangular shape and then fired in a kiln at high temperatures. The clay is usually mixed with water and other additives such as sand, Kalk, or ash to improve its strength and durability.

2.2 Manufacturing process

The manufacturing process of clay bricks involves the following steps:

2.2.1. Preparation of raw materials – The clay and shale are crushed and mixed with water and other additives.

2.2.2. Molding – The mixture is molded into the desired shape using a molding machine or by hand.

2.2.3. Drying – The bricks are then dried in the sun or in a kiln for several days.

2.2.4. Firing – The bricks are fired in a kiln at high temperatures ranging from 800°C to 1200°C.

2.3 Eigenschaften

Clay bricks have the following properties:

2.3.1. Hohe Druckfestigkeit

2.3.2. Good insulation properties

2.3.3. Geringe Wärmeleitfähigkeit

2.3.4. Good sound absorption properties

2.3.5. Low water absorption

3. What are Refractory Bricks?

3.1 Composition

Refractory bricks are made from high-quality refractory materials such as alumina, Kieselsäure, Magnesia, and zirconia. These materials have high melting points and can withstand high temperatures without breaking down or deforming.

3.2 Manufacturing process

The manufacturing process of refractory bricks involves the following steps:

3.2.1. Preparation of raw materials – The refractory materials are crushed and mixed with water and other additives.

3.2.2. Molding – The mixture is molded into the desired shape using a molding machine or by hand.

3.2.3. Drying – The bricks are then dried in the sun or in a kiln for several days.

3.2.4. Firing – The firebricks are fired in a kiln at high temperatures ranging from 1400°C to 1800°C.

3.3 Eigenschaften

Refractory bricks have the following properties:

3.3.1. Hohe Refraktionen

3.3.2. High resistance to heat and thermal shock

3.3.3. High mechanical strength

3.3.4. High chemical resistance

3.3.5. Low porosity

4. Differences between Clay Bricks and Refractory Bricks

4.1 Composition

The main difference between clay bricks and refractory bricks lies in their composition.

Clay bricks are made from natural clay and shale, while refractory bricks are made from high-quality refractory materials such as alumina, Kieselsäure, Magnesia, and zirconia.

This makes refractory bricks much more resistant to high temperatures and thermal shock than clay bricks.

4.2 Anwendungen

Clay firebricks are commonly used in construction for building walls, floors, und andere Strukturen.

They are also used in the manufacturing of fireplaces, chimneys, and other heat-resistant structures.

Feuerfeste Ziegelsteine, on the other hand, are used in high-temperature applications such as kilns, Öfen, und Verbrennungsanlagen.

They are also used in the manufacturing of glass, Stahl, and other materials that require high temperatures.

4.3 Strength and Durability

Refractory bricks are much stronger and more durable than clay bricks.

They can withstand much higher temperatures without breaking down or deforming, making them ideal for high-temperature applications.

Lehmziegel, on the other hand, are not as strong or durable and are more prone to cracking and crumbling under high temperatures.

4.4 Resistance to Heat and Chemicals

Refractory bricks have a high resistance to heat and chemicals, making them ideal for use in harsh environments.

They are able to withstand high temperatures without deforming or breaking down, and they are also resistant to the corrosive effects of chemicals.

Lehmziegel, on the other hand, are not as resistant to heat and chemicals and may break down or crumble over time.

5. How to Choose between Clay Bricks and Refractory Bricks

The choice between clay bricks and refractory bricks depends on the application.

If you are building a fireplace or chimney, clay bricks may be a suitable choice.

If you are building a kiln or furnace, refractory bricks would be a better choice due to their high-temperature resistance.

6. Advantages and Disadvantages of Clay Bricks

6.1 Advantages

6.1.1. Widely available and affordable

6.1.2. Easy to manufacture

6.1.3. Good insulation properties

6.2 Nachteile

6.2.1. Not suitable for high-temperature applications

6.2.2. May crack or crumble over time

6.2.3. Not resistant to chemicals

7. Advantages and Disadvantages of Refractory Bricks

7.1 Advantages

7.1.1. Hochtemperaturbeständigkeit

7.1.2. High mechanical strength

7.1.3. High chemical resistance

7.2 Nachteile

7.2.1. More expensive than clay bricks

7.2.2. Difficult to manufacture

7.2.3. Not suitable for low-temperature applications

8. Abschluss

Abschließend, clay bricks and refractory bricks are two types of bricks that have different properties and applications.

While clay bricks are suitable for low-temperature applications such as building walls and floors, refractory bricks are ideal for high-temperature applications such as kilns and furnaces.

The choice between clay bricks and refractory bricks depends on the specific application and the level of temperature resistance required.

9. FAQs

1. Can clay bricks be used in high-temperature applications?

No, clay bricks are not suitable for high-temperature applications as they may break down or deform under high temperatures.

2. Are refractory bricks more expensive than clay bricks?

Ja, refractory bricks are generally more expensive than clay bricks due to the high-quality refractory materials used in their composition.

3. Can refractory bricks be used in low-temperature applications?

Refractory bricks are not recommended for use in low-temperature applications as they may not provide adequate insulation.

4. What are the advantages of using clay bricks?

The advantages of using clay bricks include their wide availability and affordability, as well as their good insulation properties.

5. What are the advantages of using refractory bricks?

The advantages of using refractory bricks include their high-temperature resistance, hohe mechanische Stärke, and high chemical resistance.

Gesamt, the choice between clay bricks and refractory bricks depends on the specific application and the level of temperature resistance required.

While clay bricks may be suitable for low-temperature applications such as building walls and floors, refractory bricks are essential for high-temperature applications such as kilns and furnaces.

By understanding the differences between these two types of bricks, you can make an informed decision when choosing the right material for your project.