In recent years the demand for magnesium carbon refractories is very large after the use of magnesium carbon bricks are previously treated as industrial waste disposal, not only waste of resources and pollution of the environment.

With the magnesium resources being tenser and tenser, the product market atmosphere is more and more unsatisfactory, and controlling the production cost of magnesium carbon brick is more and more important. The used magnesium carbon bricks are recycled and processed into raw materials, which we call magnesium carbon bricks recycled materials, referred to as recycled materials. Also called used magnesium carbon bricks for waste magnesium carbon bricks.

Introducing recycled material as raw material into magnesium carbon bricks is one of the feasible ways to reduce production costs.

Because of the wide range of magnesium carbon bricks used, there are many sources of used magnesium carbon bricks. Roughly can be divided into the residual after the use of the converter, the electric furnace after the use of the residual, and the ladle after the use of the residual. And because the smelting conditions of each steel plant are not the same, the production of steel is not the same, so the formula of magnesium carbon bricks is very different, the residual magnesium carbon bricks are also uneven, so how do identify the quality of waste magnesium carbon bricks is very critical, is the most important link in the process of selection of recycled materials.

Treatment of Waste Magnesium Carbon Bricks

Magnesium carbon bricks use harsh and complex conditions, in the process of using a variety of physical and chemical changes, to make the waste magnesium carbon bricks particles material performance problems, which must be pre-treated in advance.

At present the most used method is hydration treatment, the waste magnesium carbon brick crushing and iron removal after soaking in water, and then drying to moisture less than 0.5% can be, after drying, if the conditions allow, you can use the mixing mill in the milling machine for crushing, crushing the false particles, and then finally in addition to the iron, sieving, bagging and spare.

There are many methods of hydration treatment, there are pool soaking method, water vapor method, pile watering cover film method, and so on. Inter ili, the pool immersion method is used the most. The length of the soaking time and the water temperature has a relationship, to fully hydrate the harmful impurities, according to the temperature changes in spring, summer, fali, and winter, the formulation of the soaking time regulations, from the practical point of view, the effect is very good.

Hydration is completed recycled materials need to be dried, the current stage of investment is small, and the simple operation is a simple rotary kiln.

This kiln has low production cost, high production efficiency, and large output. As the recycled material drying dust, we must do a good job of environmental protection, after drying the recycled material must be sampled regularly to test the moisture, to ensure stable quality.

Precautions for The Use of Recycled Materials

Firstly, because there are many types of recycled materials when using recycled materials must distinguish between the types and grades of recycled materials, classification, and use. Secondly, because the recycled material has many fake particles and large pores, the amount of resin added should be increased. Due to the actual production of recycled material to join the proportion of up to 60%, so more than 60% of the data is to be determined.

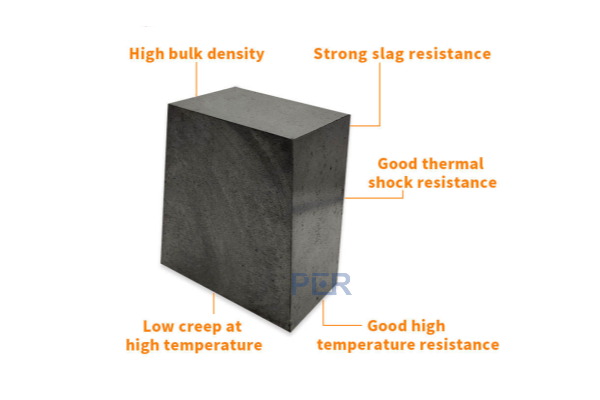

MgO-C brick (Magnesium Carbon Bricks) is currently the largest refractory used in steelmaking equipment. Its application areas are oxygen-blowing converter furnace lining, ladle, electric arc furnace lining, skid plate, and so on.

MgO-C bricks are usually made of more than 96% electrofused magnesium sand, with a small amount of antioxidant and binding agent added, which is a refractory material of good grade.

Due to the non-wetting characteristics of carbonaceous refractories, the used MgO-C bricks are less polluted and have no slag penetration.

Used MgO-C brick usually only surface or local chemical composition and structure will change, its internal structure and composition will not change. Tial, the discarded residual bricks have a high reuse value.