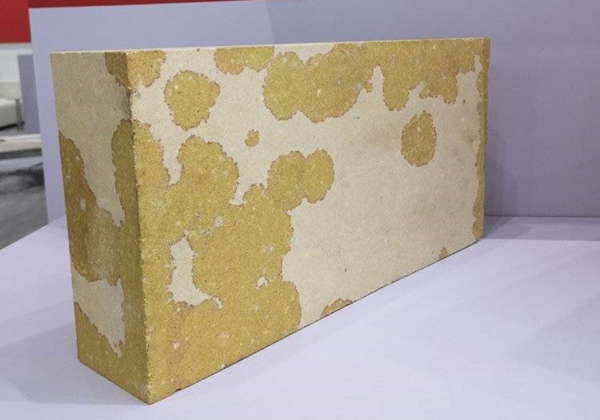

Silicon brick in the SiO2 mass fraction should be greater than 93%.

Silicon brick has more than 94% silica content. The true density is 2.35g/cm3. It has anti-acid slag erosion performance. Mas mataas na lakas ng mataas na temperatura. Load paglambot simulan ang temperatura 1620 ~ 1670 ° C.

Walang pagpapapangit sa ilalim ng mataas na temperatura para sa pangmatagalang paggamit. Mababang thermal shock katatagan (palitan ng init sa tubig ay 1 ~ 4 beses) with natural silica as raw material, plus isang angkop na halaga ng mineralizing agent, to promote the conversion of quartz in the blank to phosphor quartz.

Dahan dahan fired sa ilalim ng pagbabawas ng kapaligiran sa pamamagitan ng 1350 ~ 14 30 °C. Pag init sa 1450 °C tungkol sa 1.5 ~ 2.2 percent of the total volume expansion, Ang natitirang pagpapalawak na ito ay gupitin ang mga kasukasuan na malapit, upang matiyak na ang katawan ng masonerya ay may magandang airtightness at lakas ng istruktura. Kasabay nito, it has a long service life and reduces energy consumption.

(1) Chemical mineral composition. Silicon brick in the SiO2 mass fraction should be greater than 93%. Generally, the crystalline phase in the silica brick is squamous quartz and square quartz as well as a small amount of residual quartz, and the matrix is the glass phase.

(2) true density and bulk density. The size of the true density of the silica brick is to determine the extent of its crystalline transformation of one of the important signs. The general true density of silica brick is less than 2.388/cm3, and the true density of silica brick is 2.33-2.34g/cm3. silica is 2.65g/cm3. the higher the degree of scale quartzization, the higher the true density of fired silica brick is smaller. Kaya nga, the true density of silica bricks can determine the mineral composition of silica bricks.

Silicon brick bulk density and porosity. General silica brick porosity of 17% sa 25%, bulk density of 1.8-1.95g/cm3. Silica brick molding pressure is greater than the bulk density. Increasing the bulk density can improve the structural strength of the brick, thermal kondaktibiti, and slag resistance.

Una, the manufacture of silicon bricks selected binding agent

The binding agents used in the manufacture of silicon bricks are sulfite pulp waste liquid and milk of lime. Lime milk as a binding agent, plays the role of plasticizer. Milk of lime makes the brick in the drying process increase strength and, in the firing, become a mineralizing agent, promoting the transformation of quartz.

Lime should contain a large amount of active CaO, undecomposed CaCO3, and MgCO3 not more than 5%, Al2O3 + Fe2O3 + SO2F more than 5%. When containing large particles of underburned Ca-CO3 and overburned lime, the product produces a melt hole, affecting the quality of the product.

Batching should be converted to the addition of lime CaO, the amount of its addition depends on the different products, usually fluctuating in 1.5-2.5%. For example, the production of coke oven silica bricks, CaO addition of 2.0-3.0%; production of electric furnace top silica bricks, CaO addition of 1.4-1.75%.

Second, the dosage characteristics of silicon bricks

Adopt silica with an impurity content of less than 0.5%, and rinse it with tap water before batching to ensure the quality in the early stage. Batching will be fast conversion of quartz and slow conversion of quartz mixed ingredients, which can make the firing temperature down 20 °C. The critical particle size will be reduced from 3mm to 2mm in the batching process, which can increase the interfacial energy of the material and promote the transformation of quartz.

In addition, the selection of new mineralizing agents is also important to improve product quality. Sa kasalukuyan, most producers of the ingredients added to the mineralizing agent are still lime milk and iron scale. To improve the load-softening temperature of the product, the addition of FeO has been reduced from 2.5% to less than 1%. If the use of feldspar-type minerals containing alkali metals or composite mineralizing agents can receive better results.

Not this product should be stored in a waterproof warehouse, water wet at a temperature below 100 ℃ slow drying can still be used. Water-containing silica bricks will affect the strength after freezing, and need to be re-examined after drying.

The masonry of refractory bricks should leave expansion joints according to the expansion rate provided by the manufacturer. Refractory brick ovens or periodic use of temperature and time curves should be reasonably formulated, especially before 600 ℃ expansion intense to be strictly controlled.

Masonry refractory bricks use mud quality to be compatible with the refractory bricks, sometimes Refractory brick damage is due to the refractory bricks’ joints being first etched leading to alkali vapor into the previously introduced masonry refractory bricks joints requirements.

Now some glass factories to increase the melting temperature and extend the overall life of the kiln, the small furnace mouth, and chest wall use electrofused zirconium corundum refractory bricks, and some of the vault or part of it to use other materials.

The Silicon brick consumption ratio may be smaller, but the silicon brick has a high load softening temperature, lightweight, low price, and other potential, the glass kiln arch and part of the upper structure of the furnace will still use silicon brick. Kaya nga, improving the quality of glass kiln refractory bricks still can not be ignored.

Mula noong Oktubre, Patuloy na tumaas ang presyo ng alumina, and China's largest bauxite importer - a…

Una, Mataas na Alumina Brick: The Leader In High Temperature Refractories As a leader in high-temperature…

The application of refractory bricks in the kiln immediately endangers the operation rate of the…

Analysis Of The Causes Of Common Quality Problems In Tunnel Kiln Construction And Measures To…

Corundum quality refractory castables are made from corundum to the new jade refractory insulation material…

Pagsusuri Ng Aluminum-Silicon Refractory Raw Materials Prof. Li Yong of the University of Science and…