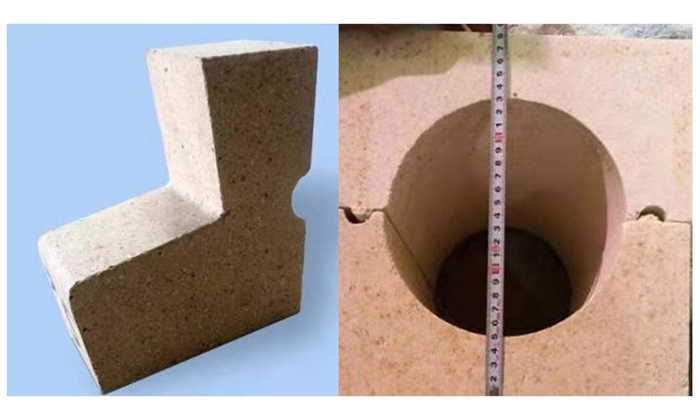

Mattone andalusite

Con contenuti elevati di al2o3 e contenuto a basso impurità, L'Andalusite è un materiale refrattario di alta qualità ideale. Mattoni refrattari andalusite avere un'eccellente conducibilità termica bassa, elevata resistenza alla corrosione scotta, e resistenza al creep. I mattoni alunite refrattari hanno un'alta resistenza termica, bassa porosità, Resistenza alla deformazione a goccia di scheggiatura e compressione, resistenza allo shock termico, e buona refrattarietà.

I mattoni andalusite sono usati principalmente nelle pareti di raffreddamento, porte del forno al coke, fodera per stufa calda, reticolo, E così via in Blast Furnace, chimico, e industrie in ceramica. I mattoni refrattari possono anche essere applicati sulla parte superiore di alcuni forni metallurgici, L'effetto è migliore dei mattoni di silice.

Per refrattari è un produttore professionista di mattoni refrattari andalusite. Offriamo di alta qualità andalusite mattoni e non ferito andalusite mattoni. Puoi contattarci in tempo per ottenere il economico andalusite Prezzo di mattoni.

Parametri di mattoni standard andalusite

| Indice | GX-135 | GX-140 | GX-150 | |

| Al2O3 | (%) ≥ | 65 | 65 | 65 |

| Fe2O3 | (%)≤ | 1.5 | 15 | 1 |

| Densità apparente | (g/cm3) ≥ | 2.4 | 2.5 | 2.6 |

| Porosità apparente | (%)≤ | 22 | 22 | 20 |

| Forza di frantumazione a freddo | (MPa) ≥ | 60 | 60 | 80 |

| 0.2Refrattarietà MPA sotto carico | ℃ ≥ | 1520 | 1550 | 1600 |

| Refrattarietà | ℃ ≥ | 1790 | 1790 | 1790 |

| (0.2MPa, 20-50H, %)Tasso di scorrimento | (%) | 0.2 | 1400℃ | 1400℃ |

| 0.2 | 0.2 | |||

| Resistenza agli shock termici (1000℃, acqua, spegnimento, ciclo) | ℃ | 15 | 20 | 20 |

Advantages of PER's Andalusite Refractory Bricks:

1. Resistenza ad alta resistenza e usura rispetto ai tradizionali mattoni di allumina alta.

2. Eccellente stabilità di shock termico. Aumentare la durata del rivestimento del forno e ridurre il costo dei materiali refrattari.

3. Eccellente resistenza all'erosione.

Per i mattoni refrattari andalusite fabbricati sono adatti per gli altiforni, altiforni caldi, Forni di equalizzazione, giri d'acciaio, forni rotativi per cemento, forni a tunnel in ceramica e forni di vetro, e altre industrie.

La differenza tra i mattoni della mulite andalusite e i mattoni di allumina ad alto livello

Mattone di allumina ad alta allumina

I mattoni di allumina ad alta allumina sono realizzati in andalusite come materia prima principale, con la bauxite aggiunta, dopo lo stampaggio ad alta pressione, asciugatura, e sparare a 1500 ℃.

Il mattone di allumina ad alta allumina è caratterizzato da resistenza ad alta temperatura, Temperatura elevata di ammorbidimento sotto carico, e bassa velocità di scorrimento ad alte temperature, e non utilizzato nel volume di stabilità volumetrica ad alta temperatura, L'uso del coefficiente di espansione termica è un piccolo, basso coefficiente di conducibilità termica.

Mattone di mulite andalusite

Il mattone della mulla rutilato è un tipo di mattoni refrattari realizzato aggiungendo diversi rapporti di mulite rutilata e mulite al composito.

Questo tipo di mattone antincendio ha i vantaggi della buona resistenza all'ossidazione, forte refrattarietà, elevata resistenza alla compressione, basso gravità specifica, Buona resistenza alle peeling, resistenza alla flessione ad alta temperatura, e lunga durata.

Refrattari andalusite 1830 ℃, Resistenza alla corrosione chimica, Aggiunta di andalusite in mattoni refrattari ad alta allumina, può fare elevati mattoni di allumina con resistenza all'abrasione e una maggiore temperatura di ammorbidimento sotto carico, Migliore resistenza alle prestazioni rapide del freddo e del calore. Può densificare le articolazioni di mattoni ad alte temperature e migliorare la compattezza complessiva della muratura di mattoni di allumina alta, migliorando così la resistenza alla permeabilità delle scorie.

In breve, Mullite e eritriti di eritrite I mattoni di allumina hanno lo stesso ma hanno anche una grande differenza, I mattoni di mulite di eritrite rispetto al prezzo di mattoni di allumina alta eritrite è superiore all'eritrite ad alta allumina mattoni a temperatura ad alta temperatura resistenza all'erosione ad alta temperatura, mattoni di mulite eritrite Una buona flessibilità, La resistenza alla buccia è un po 'più forte.

Caratteristiche dei mattoni andalusiti

I mattoni refrattari andalusite sono realizzati in andalusite come materia prima, Aggiunta di polvere di silice, Polvere di mulite, e altre polveri.

Questi materiali sono in proporzione all'aggiunta del legante, e rigoroso controllo della dimensione delle particelle di materia prima, grado, e è TiO2, R2O, e altre impurità, dopo il dosaggio, miscelazione, modanatura, asciugatura, e cottura ad alta temperatura.

Questo può soddisfare le moderne Blast Furnace Hot Blast Furnace diverse parti, Diversi ambienti di lavoro utilizzano, Migliorare la durata della durata dell'altaforno della fornace calda è di grande significato.

I mattoni di fuoco refrattario andalusite verranno trasformati in mullite mediante riscaldamento, e dopo la trasformazione, ha prestazioni refrattarie più elevate.

I rifrattori possono raggiungere più di 1800 ℃, I mattoni eritriti hanno poche impurità, e il declino della forza ad alta temperatura è molto piccolo.

È anche resistente al rapido freddo e al calore, ha un'elevata resistenza meccanica, forte resistenza agli shock termici, forte resistenza a scorie, punto di conversione ad alto carico. E ha una stabilità chimica molto alta (anche insolubile in acido idrofluorico) e resistenza alla corrosione chimica molto forte.

Uso industriale di andalusite, principalmente per assumere il suo ruolo nella resistenza ad alta temperatura. Andalusite a pressione atmosferica riscaldata a 1350 ℃, Dopo l'inizio della trasformazione in mulite ad ago. I cristalli di mulite sono l'unica forma di alluminosilicato che è stabile ad alte temperature.

Informazioni su PER Refractories Company

PER Società di refrattari si trova nella città di Xinmi, Provincia di Henan, la città natale di materiali refrattari in Cina. La nostra azienda è un'impresa refrattaria basata sulla tecnologia che integra R&D, produzione, saldi, e servizio tecnico. Le ricche risorse e l'eccellente qualità del territorio forniscono condizioni superiori senza pari per la produzione di materiali refrattari. I nostri prodotti principali sono mattoni di argilla refrattaria, mattoni refrattari ad alto contenuto di allumina, mattoni refrattari di silice, mattoni refrattari al magnesio, mattoni di mullite, mattoni isolanti, e altri prodotti resistenti alle alte temperature.

PER considera la cosa più importante, crediamo nel prendere sul serio ogni prodotto e nel ricevere sinceramente ogni cliente. Fornire risultati rapidi e di alta qualità a tutti i nostri clienti. PER Refractories sarà il produttore di refrattari più affidabile e il partner affidabile.

Azienda PER refrattario è la base di produzione di verde, risparmio energetico, e nuovi materiali refrattari rispettosi dell'ambiente. La nostra azienda ha superato ISO9001:2008 certificazione internazionale del sistema di qualità e GB/T24001-2004 / ISO14001:2004 certificazione del sistema di gestione ambientale, certificazione dell'agenzia di ispezione di qualità aziendale. I nostri prodotti sono venduti bene in più di 20 paesi di tutto il mondo. Sono i prodotti refrattari preferiti per la metallurgia, non ferroso, petrolchimico, bicchiere, ceramica, e altre industrie refrattarie.