It is for this reason that they also reduce the thermochemical stability of refractory bricks. This is especially true when acting on grain boundary melt formation (e.g. Fe203 etc.).

High purity, lav porøsitet, coarse grain magnesia is the raw material for the production of special magnesium refractory bricks. To promote the grain growth of magnesite, the method of adding a small amount (mindre enn 0.5%) of Cr203, FE203, ZrO2, as well as oxides and salts of V, Mn, A1, Cu, and rare earth elements was used in the past. Although these substances promote MgO densification and grain growth by different mechanisms. derimot, they are all achieved using accelerated diffusion.

It is for this reason that they also reduce the thermochemical stability of refractory bricks. This is especially true when acting on grain boundary melt formation (e.g. Fe203 etc.). This means that if the thermochemical stability of magnesium refractory bricks is not to be reduced, the addition of other foreign substances to their interior should be avoided.

In the case where no foreign substances are added, the technical measure is to use 500 pre-treatment of magnesium hydroxide or 900°C pre-treatment of magnesite, followed by treatment of reactive MgO material (fine grinding). The special magnesia is produced by adding or not adding inert MgO species before balling/briquetting, then high-pressure balling/briquetting and later sintering in a high-temperature kiln.

All of these technical measures reduce the porosity that prevents crystallization, improve the densification and, in the absence of sintering accelerators, also lead to the growth of magnesite grains. If this is done in a rotary kiln, then even if the upper temperature (1900 to 2000°C) is reached. And prolong the time within. To increase the intensity of calcination. If no special measures. This can only obtain the magnesium sand with a grain diameter of about 50~120μm. If you need to obtain a larger grain of magnesium sand. Then you need to use the vertical kiln for the production of large grain sintered magnesium sand dead firing kiln.

The dead firing temperature of the vertical kiln can reach 2100~2300℃ even under the condition of no oxygen enrichment. This can make the average square magnesite grain diameter of low-iron sintered magnesia reach more than 2001Lm.

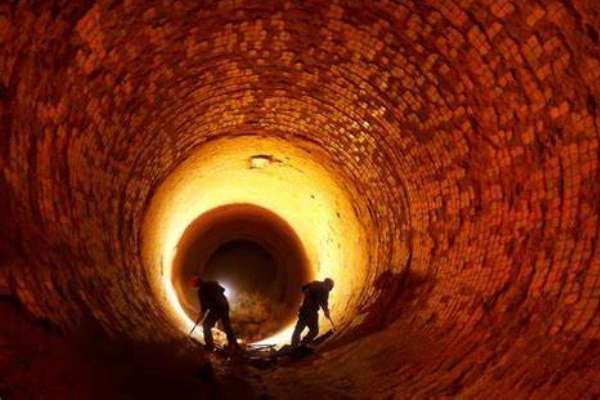

The refractory bricks lining the sintering belt of the high-temperature vertical kiln producing the above magnesia should satisfy (1) no pollution to the high purity magnesia, og (2) be able to adapt to the operating conditions of 2100~2300℃. Derfor, high-purity special magnesium refractory bricks should be selected to build the sintering belt.

These magnesium refractory bricks are usually selected as raw material production of 99% purity of MgO, bulk density of not less than 3.40g/cm3 coarse grain magnesium sand. Its performance indicators for MgO are 98% ~ 99%.

Refractory brick density of 3.0g/cm3 Pa ≤ 17%, T ℃ ≥ 1800 ℃. Other parts (pre-tropical band and cooling band) are selected MgO content of 97.5 % ~ 98% of high-purity magnesium brick masonry.

High-temperature refractory brick masonry methods are many, and they have a great impact on the quality of the kiln brick, generally through some of the following requirements to evaluate.

1. Safety of operation

2. Correct and skillful installation

3. Bricklaying time

4. Handling of the bricklaying equipment (fleksibilitet).

1. The wet laying method is mainly used for clay brick, and high alumina brick two. The wet laying method, high-temperature refractory bricks, and refractory mud refractoriness must be relatively close, otherwise, it will run, kiln bricks did not wear, but the refractory mud is no longer, so it is easy to drop bricks. The refractory clay should be applied evenly.

2. The dry laying method is mainly used for dolomite bricks and magnesium chromium bricks, mainly because these two kinds of bricks are susceptible to water to affects their quality.

1. Akkurat nå, the longitudinal staggered masonry method is less used, although it is better than the overall strength of the school, more closely linked to each other, when the problem occurs, a smaller point of destruction may be a result of a larger surface damage.

2. Horizontal ring masonry can be divided into two adjacent brick circle brick seams into a straight line and brick seam staggered two masonry. The brick seam is a straight line, due to brick size deviation or bricklaying., Brick circles of staggered, brick corners are easy to break and may cause bad strength.

1. Akkurat nå, the rotary method is only used for some small kilns, for large kilns, there is a huge pressure when supporting the kiln will make the kiln shell deformed. Kiln support is bulky, handling support is not convenient, the larger the diameter of the kiln, the kiln support to withstand the force will be the greater, easy to danger, and bricklaying speed is relatively slow.

2. The gluing method, does not need auxiliary tools, bricklaying speed. However the glue method is mainly difficult to ensure the quality of kiln bricks, there is no way to determine whether the bricklaying circle is solid. For the end of the brick, unevenness is difficult to deal with. Brick laying before the kiln is required to be very clean, otherwise, it will affect the effect of adhesive bonding.

3. Fixed method The lower half of the kiln shell is manually laid, and the upper half of the circle is fixed with a bricklaying machine. High-temperature refractory bricks do not need to turn the kiln in the process of laying firebricks, and bricks can be laid in any place of the kiln section, The bricklaying machine is very convenient to move in the kiln. Bricklaying is fast, effektiv, and safe.

PER Refractories produces a wide range of products including lightweight heat-insulating brick series, leire murstein, høy alumina murstein, magnesium murstein, acid-resistant, alkali-resistant, and low creep series bricks, Nøytral ildfast serie, and a variety of high-temperature special refractories. Our products are the preferred refractory products for metallurgy, glassovner, keramiske ovner, non-ferrous metal products, petrokjemiske produkter, refractory materials and other industries.

Siden oktober, aluminaprisene har fortsatt å stige, and China's largest bauxite importer - a…

Først, Høy alumina murstein: The Leader In High Temperature Refractories As a leader in high-temperature…

The application of refractory bricks in the kiln immediately endangers the operation rate of the…

Analysis Of The Causes Of Common Quality Problems In Tunnel Kiln Construction And Measures To…

Corundum quality refractory castables are made from corundum to the new jade refractory insulation material…

Analyse av ildfaste aluminium-silisiumråmaterialer Prof. Li Yong of the University of Science and…