Cegła magnezji

Magnesia refrakcyjna cegła jest materiałem opornym na magnezycie, Piasek Water Water Magnesia, i dolomit jako surowce, magnesyt jako główna faza krystaliczna, i zawartość tlenku magnezu powyżej 80%.

Jest to alkaliczny materiał ogniotrwały. Materiał ogniotrwały magnezji jest jednym z szeroko stosowanych materiałów pomocniczych w przemyśle metalurgicznym ze względu na jego wysoką wydajność oporową, Siła wysokiej temperatury, i odporność na ługowanie żużla alkalicznego.

Punktem zmiękczania obciążenia i odpornością na wstrząsy termiczne cegły magnezji o wysokiej czystości są znacznie lepsze niż ogólne cegły magnezji. Wysokie refraktory, Dobra odporność na żużla alkaliczne, a żelazne żużla są ważnymi materiałami refrakcyjnymi wysokiej jakości.

Na firmę, jako Profesjonalny producent cegieł ogniotrwałych w Chinach, może zapewnić niższe ceny niż rynek. Skontaktuj się z nami teraz, aby uzyskać najnowszą cenową cegły Magnesia.

Rodzaje i charakterystyka cegieł ogniotrogicznych magnezji

Produkty z cegły ogniotrwałej magnezji są produkowane głównie metodą spiekania, Temperatura strzelania wynosi na ogół między 1500 ~ 1800 ℃, Ponadto, Można również dodać środek wiązania chemicznego, aby nie spalać cegieł i nieokreślonych materiałów oporowych. Na oporne cegły magnezji używane głównie w płaskich piecach, piece elektryczne, Konwertery utleniania, Nieżelazne metalowe piece, piece cementowe, alkaliczne oporne na kalcyna, itp.

Produkty te można podzielić na dwie kategorie: Produkty metalurgiczne magnezji i magnezji. Według składu chemicznego i użycia można podzielić na metalurgiczny piasek magnezowy, cegły magnezowe, Krzemowe cegły magnezowe, Aluminiowe cegły magnezowe, Cegły wapnia magnezu, Cegły węglowe magnezu, i inne odmiany. Na jego wydajność ma duży wpływ na stosunek CAO/SIO2 i zanieczyszczenia.

Cegła magnezu

Najważniejsza cegła w alkalicznych refraktiach, to wysoka refraktory, Dobra odporność na erozję tlenków żelaza, żużla alkaliczna, i wysoki stopień wapnia.

Cegła magnezu wystrzeliła cegła magnezu i nie spaliła cegły magnezu, Temperatura strzelania z cegły magnezu jest ogólnie 1550-1600 ℃, Temperatura strzelania z cegły o wysokiej czystości 1750 ℃, lub nawet wyższy.

Cegły magnezowe są szeroko stosowane w podszewkach pieca stalowego, piece ferroalloy, żelazne piece mieszające, Nieżelazne metallurgiczne piece przemysłowe, Kiln wapna, piece tunelowe i tak dalej w branży żelaza i stalowej.

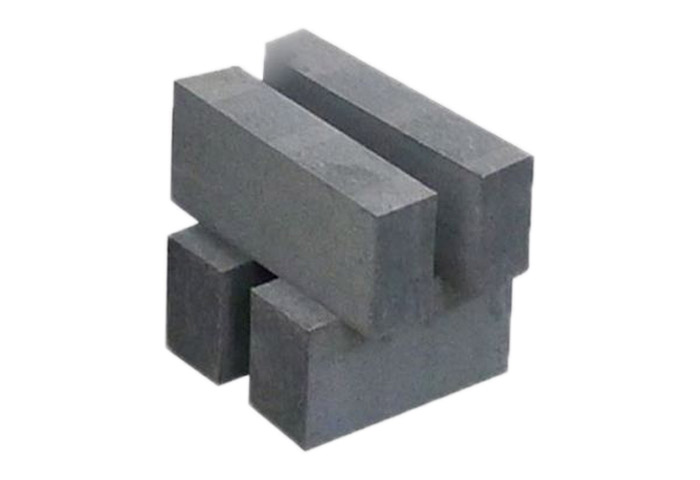

Cegła węglowa magnezu

Magnezja cegła węglowa jest wykonana z wysokiej temperatury topnienia tlenku alkalicznego tlenku magnezu (Punkt topnienia 2800 ℃) i materiał węglowy o wysokiej temperaturze topnienia, którego trudno jest infiltrować żużla jako surowiec. Dodaj różnorodne dodatki nietlenkowe, z środkami wiązania węgla w połączeniu z nieleczących się oporności z kompozytem węglowym.

Cegły magnezu-węglowe są używane głównie do wewnętrznej podszewki konwertera, Piec łukowy AC, DC Arc Piec, linia żużla, i inne części. Cegła węglowa magnezu jako kompozytowy materiał oporowy, Skuteczne zastosowanie odporności na żużę z piaskiem magnezu, oraz wysoka przewodność cieplna i niskie rozszerzenie węgla kompensują odporność na piasek magnezu.

Cegła magnezowo-aluminiowa

W porównaniu z cegłą magnezową, cegła magnezowo-aluminiowa ma dobrą odporność na szybkie zamrażanie i szybkie nagrzewanie oraz może wytrzymać chłodzenie wodą 2025 czasy, lub nawet więcej razy, co jest wyjątkową zaletą cegły magnezowo-aluminiowej.

Ogniotrwałość cegieł magnezowo-aluminiowych przekracza 2000 ℃, odporność na szybkie chłodzenie i nagrzewanie jest lepsza niż cegieł magnezowych, i może wytrzymać erozję alkalicznego żużla. Stosowany jest do budowy dachów alkalicznych pieców płaskich i pieców elektrycznych do hutnictwa stali.

Cegła wapnia magnezu

Magnesyt jest głównym składem mineralnym, z krzemianem Trialcium i krzemianem Dicalcium jako kombinacji.

Oprócz słabej stabilności wstrząsu termicznego, Inne wskaźniki wydajności niż cegła magnezu są lepsze.

Cegły magnezu-kalcium są używane głównie jako podszewka pieca AOD do wytapania stali nierdzewnej i okładziny VOD Ladle. Zastąpienie oryginalnej cegły magnezu-chromowej, jest to najważniejszy materiał ogniotrwały.

Krzemowa cegła magnezu

Square Magnesite jest głównym składem mineralnym, z Magnesia Olivine jako wiązaniem matrycy.

Jego wydajność i cegła magnezu są mniej więcej takie same.

Ale temperatura zmiękczania obciążenia jest wyższa niż cegła magnezu, a odporność na żużla jest również lepsza.

Cegły magnezu-silica są używane głównie w stalowym piecu do toczenia, Ogrzewany piec na dole, ale również używane jako szklana cegła kratowa., itp.

Indeks techniczny

| Wydajność produktu | Alumina Magnesia Carbon Brick | Magnesia aluminiowa cegła węglowa | Cegła węglowa Magnesia | ||||

| Skład chemiczny (%)≥ | AL2O3 | 65 | 70 | 10 | 15 | ||

| MG0 | 15 | 10 | 75 | 70 | 78 | 74 | |

| C | 7 | 7 | 10 | 8 | 10 | 14 | |

| Pozorna porowatość (%) ≤ | 5 | 5 | 3 | 3 | 3 | 3 | |

| Gęstość luzem (g/cm³)≥ | 3 | 3 | 3 | 3 | 3 | 2.9 | |

| Wytrzymałość na ściskanie w normalnej temperaturze (MPa)≥ | 40 | 40 | 40 | 40 | 40 | 40 | |

| Wysokiej temperatury Siła zginania(MPa)≥(1400℃ x 0,5H) | 6 | 6 | 7 | 7 | 6 | 8 | |

| Aplikacja | stopiony pulę, dół kadzi | stopiony pulę | linia żużla | ||||

Różnica między cegłą tlenku glinu a cegłą magnezową

High Alumina Brick to seria produktów aluminiowych i krzemowych, A cegła magnezu to seria produktów magnezu.

High Alumina Cegła może oprzeć się słabej alkalicznej i słabej atmosferze kwasowej i jest neutralnym produktem. Cegła magnezu opiera się silnej erozji alkalicznej, nie może być stosowane w kwaśnej atmosferze i należy do produktów serii alkalicznych.

High Alumina Cegła i cegły magnezowe to dwa różne materiały i charakter produktów opornych, Gęstość cegły magnezu jest powyżej 3.0, Punktem topnienia przy 2850 ℃, Gęstość cegieł o wysokiej cegierze tlenku glinu 2.3, Punkt topnienia na 1500 ℃.

Cegły magnezowe

1. Refraktory cegły magnezu wynosi ponad 2000 ℃, a ładunek miękki wynosi 1800 ℃.

2. Ale cegła magnezu ma wysoką przewodność cieplną, Słaba odporność na wstrząsy termiczne, i wysoki stopień odporności na ciepło.

3. Magnesium brick's resistance to acidic slag is poor, i nie może bezpośrednio kontaktować się z kwaśnymi produktami.

4. Jeśli kwas znajduje się w podszewce pieca, Użyj cegły o wysokiej glinu zostanie oddzielone od niej do użycia.

5. And the magnesium brick's resistance to hydration is poor, Łatwo spotkać wodę długie białe włosy, ale także powoduje pęknięcia, Zmniejszona siła.

6. Cegła magnezu w przechowywaniu i transporcie na wszystkich, aby zapobiec wilgoci, deszcz, i śnieg.

Cegły o wysokiej zawartości tlenku glinu

1. Refraktory cegły o wysokiej glinu są powyżej 1700 ℃.

2. Obciążenie zmiękczanie temperatury w temperaturze 1520 ℃, najwyższy nie przekracza 1600 ℃.

3. Temperatura zmiękczania obciążenia cegły o wysokiej glinu jest również bardzo różna w zależności od różnych gatunków surowców.

4. Temperatura zmiękczania cegieł o wysokiej cegie glinu wynosi również 1410 ℃.

5. Chociaż cegła wysokiej aluminiowej jest neutralna cegła, Stabilność wstrząsu termicznego jest dobra, nie boję się nawodnienia, i może być stosowany w słabych alkaliach, Słaba kwaśna atmosfera.

Streszczać

Tak więc w różnych podszewkach pieca o różnych temperaturach, Wybór cegły magnezu lub cegły o wysokiej glinu wynika z wybranego stopnia erozji i atmosfery. Atmosfera alkaliczna musi wybrać cegłę magnezową. Używając temperatury poniżej 1400 ℃, Słaba alkaliczna lub słaba kwaśna atmosfera może wybrać cegły o wysokiej glinu.

Różnica między cegłą tlenku glinu a cegłą magnezową polega na tym, że materiał jest inny, Temperatura użycia jest inna, Atmosfera odporna na erozję jest inna, a efekt szoku termicznego jest inny. Inną różnicą jest cena rynkowa, High Alumina Cena jest niska, A cegła magnezu jest wysoka. Oczywiście, Jako profesjonalny dostawca materiałów ogniotrwałego z wieloletnim doświadczeniem produkcyjnym i eksportowym, Możemy zaoferować niższą cenę niż cena rynkowa.

O firmie PER materiałów ogniotrwałych

Firma materiałów ogniotrwałych PER znajduje się w mieście Xinmi, Prowincja Henan, rodzinne miasto materiałów ogniotrwałych w Chinach. Nasza firma jest opartym na technologii przedsiębiorstwem zajmującym się materiałami ogniotrwałymi, integrującym R&D, produkcja, obroty, i serwis techniczny. Bogate zasoby i doskonała jakość na tym terytorium zapewniają niezrównane, doskonałe warunki do produkcji materiałów ogniotrwałych. Naszymi głównymi produktami są cegły ogniotrwałe, cegły ogniotrwałe o wysokiej zawartości tlenku glinu, Krzemionki ogniotrwałe cegły, cegły ogniotrwałe magnezowe, cegły mulitowe, cegły izolacyjne, i inne produkty odporne na wysokie temperatury.

Firma PER materiał ogniotrwały jest bazą produkcyjną surowca zielonego, oszczędzanie energii, i przyjazne dla środowiska nowe materiały ogniotrwałe. Nasza firma przeszła ISO9001:2008 międzynarodowy certyfikat systemu jakości i GB/T24001-2004 / ISO14001:2004 certyfikacja systemu zarządzania środowiskowego, certyfikacja agencji kontroli jakości w przedsiębiorstwie. Nasze produkty są dobrze sprzedawane w ponad 20 krajów na całym świecie. Są preferowani produkty ogniotrwałe dla metalurgii, nieżelazne, petrochemiczny, szkło, ceramika, i innych gałęziach przemysłu materiałów ogniotrwałych.