Refractory Fiber

Refractory materials with a fiber structure are a new variety of highly efficient refractory materials. De acordo com a composição da fase, divida-a em vítrea, vidro microcristalino (Vidro microcristalino de silício cítara) e fibras cristalinas (whiskers or viscose filaments). According to the fiber length: long fibers artificial short fibers and short fibers. Long fiber materials are made based on silica (quartz glass fibers) and the following binary systems: SiO2-ZrO2, SiO2-HfO2, SiO2-GeO2, and SiO2-ThO2 materials.

The typical property of a fiber material is that it has a high strength to tensile forces. On some occasions, the fiber strength is close to the theoretical strength of the material. Por exemplo, when the theoretical strength is 2-2.5 MPa, the tearing strength of quartz fiber in a liquid nitrogen medium is 1.8 MPa.

As the fiber coarseness decreases, its strength increases. Reasons for high strength: reduced probability of the presence of dangerous structural defects (cracks) in specimens with very small dimensions; homogeneous structure. Orientation of the structure and microcracks follow the fiber axis.

The modulus of elasticity of the fibrous material is weakly or not related to the fiber diameter. Because of this, the larger relative deformation of the thread is much larger than that of a large specimen. Portanto, the deformability (which in turn implies thermal shock resistance) of fibers is somewhat higher than that of large specimens. This becomes the second property of the fiber material. The density of the fiber itself is equal to the density of the large specimen, however, with many fibers composed of products, in sufficient strength, its bulk density is much smaller.

This situation is used to manufacture fiber-insulating refractories. The application of such refractories, technically not only to promote the reduction of heat loss but also to solve the problem of reducing material consumption. The thermal insulation properties of fiber materials become its third typical characteristic. Fiber materials are close to lamellar crystalline materials and hollow spheres according to the nature of their strength.

The refractory materials industry has more practical significance for the A12O3-SiO2 system, multi-product fiber materials and carbon, SiC linear crystalline, e assim por diante. Composites (hybrids) consisting of fibers and matrices (heavy substances) are also of great interest. Where high strength is matched with relatively low bulk density. This material is very promising in terms of quantity and is about to increase within the production of ordinary refractory materials. Because the composite technology can have a variety of good properties of the composition of the concentration, this method can produce pre-specified high-performance refractory fiber insulation refractory materials.

Refractory Fiber Heat Transfer

Refractory fiber heat transfer is the main medium of gas, with refractory fiber porosity of more than 90%, the gas composition in the pores directly affects the thermal conductivity of refractory fiber. The heat transfer of refractory fiber is a logarithmic curve, the thermal conductivity value rises faster after the temperature is higher than 700℃.

Heat Transfer Mode

Heat transfer refers to the spontaneous flow of heat from the high-temperature region to the low-temperature region, and is a kind of energy transfer phenomenon caused by the temperature difference. In nature, whether within a medium or between two media, as long as there is a temperature difference exists, there will be a heat transfer process.

We refer to the amount of heat transferred out of or into an object per unit of time as heat flow. The heat flow per unit of time perpendicular to the direction of the heat flow is called the heat flow density.

According to the physical mechanism of heat transfer, there are 3 ways of the heat transfer process: condutividade térmica, convection, and radiation.

Refractory Fiber Classification

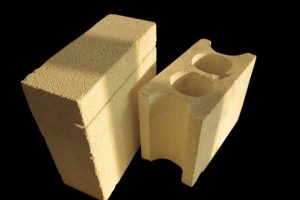

Refractory fiber (also known as ceramic fiber) material is a new type of refractory material developed in recent decades. It overcomes the inherent brittleness of refractory bricks and unshaped refractory materials, portanto, the scope of use is rapidly expanding.

Refractory fiber furnace wall has many points: resistente ao calor, good insulation properties, small heat storage, leve, under the same conditions to obtain a thinner, lighter furnace wall; elasticidade, good resistance to mechanical vibration and heat shock resistance, and good electrical insulation and sound absorption and other properties. Simple structure, convenient construction, suitable for complex shape parts. Desvantagens: poor scour resistance. Portanto, it is not suitable to be used in the convection chamber with a soot blower and chimney with a large flue gas flow rate.

According to Henan Refractories Factory experts, refractory fiber is divided into three categories according to its chemical composition:

1. Ordinary aluminum silicate refractory fiber, containing AL2O3 46% ~ 48%, SiO2 52% ~ 53%, o uso da temperatura 1000 ~ 1200 ℃.

2. High-alumina refractory fibers, containing AL2O3 56% ~ 64%, SiO2 35% ~ 44%, using temperature 1200 ~ 1400 ℃.

3. Chromium-containing aluminum silicate refractory fiber, containing Cr2O3 4%, o uso da temperatura 1300 ~ 1400 ℃.

According to the shape of the products, there are felt, blanket, paper, tape, rope, and shaped products. Hoje, the refractory fiber used in the tube furnace wall, generally containing about, only direct contact with the surface of the flame, only with high-alumina refractory fibers containing Al203 60%, and methylcellulose as a binder for the soft felt. Its heat-resistant, heat preservation performance is better, because its price is more expensive, and it is only used as a refractory layer. The insulation layer is generally cheap rock wool board or slag cotton board.