Lightweight high-temperature refractory bricks of the leading products Department of polycrystalline mullite fibers have a small heat capacity, small capacity, low thermal conductivity, and thermal sensitivity of good thermal insulation materials. In a broad sense, belongs to the indefinite refractory heat insulation materials, including high-temperature refractory fiber and its composite products of two types.

Lightweight High-Temperature Refractory Bricks Application Range

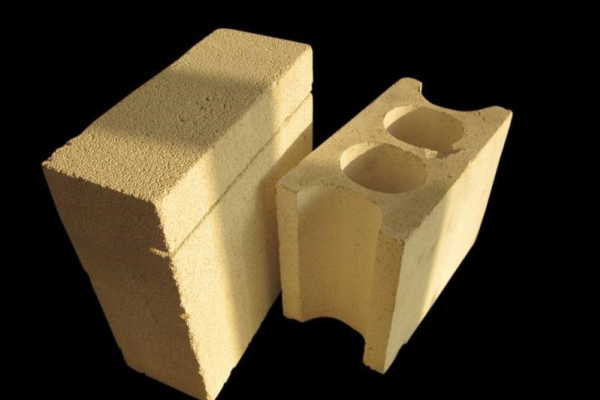

Lightweight high-temperature bricks have good resistance to rapid cooling and heating, low specific heat, and low linear expansion properties, weighing 100-600kgm3 (fiber can reach 80kgm3). It has a certain degree of seismic performance, the product is resistant to scouring, easy to process, with flexible construction and, a short construction period, can be processed into a variety of indeterminate cotton, bricks, boards, felts, blankets, standard products according to the needs of different industries. The products are suitable for insulation and sealing of kiln linings in metallurgy, chemical industry, machinery, electronics, glass building materials, military industry, scientific research aerospace and aviation, etc. below 1600℃. It can replace imported refractory materials and construct all-fiber kilns, which has a wide range of applications and good prospects for market development.

Application Of Lightweight Refractory Bricks For Kiln Lining At High Temperature

According to the different requirements of furnace temperature and working environment, different types and thicknesses of lightweight high-temperature refractory materials are chosen as the inner lining. Not only can the fire reduce the thickness of the kiln wall, but it also can greatly reduce the amount of kiln bundle, and speed up the kiln heating speed.

Kiln heating time is as much as 18 times faster. Therefore, lightweight high-temperature refractories are now widely used in the ceramic industry shuttle kiln, tunnel kiln, roller kiln, machinery industry bell kiln, as well as other thermal equipment for kiln lining. Like steel varieties and specifications of frequent changes in the rolling mill continuous heating furnace on the application of lightweight high-temperature refractory materials for lining, its comprehensive energy saving up to 56%; for intermittent electric heating furnace for lining, its energy saving is more obvious.

The use of lightweight high-temperature refractory materials for furnace lining, not only can save natural gas to bring exceptionally significant energy-saving effects, but also can extend the life of the furnace lining, reduce the maintenance cycle, and reduce maintenance costs.

Lightweight High-Temperature Refractory Castables For Kiln Filling And Sealing

Lightweight high-temperature refractory castables can not only be used as kiln liners (or whole furnace liners) in industrial kilns. But also as a high-temperature kiln filler sealing and thermal insulation material. Widely used in kiln heating element of the furnace wall gap and the gap of the gold flexure parts, roller kiln two ends of the head of the rotating part of the hole, out of the top of the kiln seams, kiln car, and joints, as well as kiln door, furnace cover filling or sealing especially lightweight high-temperature refractory material itself has the elasticity and filling properties. In the high-temperature kiln below 1600 expansion joints can relieve the brick wall expansion thermal stress, and reduce heat loss.

Lightweight High-Temperature Refractory Construction Of All-Fiber Furnace

The thermal conductivity of lightweight high-temperature refractory is very small, the fiber products are only 16% of the traditional refractory bricks, the bulk weight is only 125, and the heat storage capacity is only 110130 of the heat storage capacity of the brick lining, therefore, the whole kiln wall and lining are made of lightweight high-temperature refractory, which can speed up the firing speed, and improve the output and quality of the products.