Satış için Firebricks

Refrakter tuğlalar alüminosilikattır Ateş Refrakter Tuğlalar AL2O3 içeriği ile 30% yada daha fazla. Firebrick, yüksek sıcaklık teknolojisi için temel bir malzemedir ve çeşitli endüstriyel fırınlarla çok yakın bir ilişkiye sahiptir.. Farklı refrakter tuğlalar, kimyasal mineral bileşimindeki farklılıklar nedeniyle farklı temel özellikler göstermektedir., mikro yapı, ve üretim süreci.

Refrakter şirket başına Ateş kil tuğlaları dahil yüksek kaliteli refrakter tuğlalar üretir, yüksek alümina refrakter ateş tuğlaları, Silika Ateş Tuğlaları, Magnezya Ateş Tuğlaları, mulit ateş tuğlaları, ve yalıtım ateş tuğlaları, vesaire.

Bu sırada, Refrakter Firebrick ürünlerimizle ilgileniyorsanız, veya bir fırın veya ocak inşa etmeyi planlıyorsanız, bizimle iletişime geçebilirsiniz! Profesyonel tavsiye ve rekabetçi fiyatla size hemen cevap vereceğiz

Ateş Tuğlaları Ürünleri Türleri

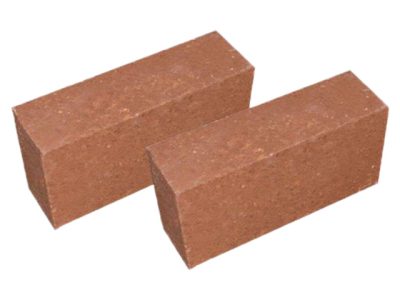

Ateş tuğlaları

Premium ateş tuğlalarımız şömineler inşa etmek için mükemmeldir, fırın, ve fırınlar. Onlar yoğun, ısıya dayanıklı, ve aşırı sıcaklıklara dayanacak şekilde tasarlanmış.

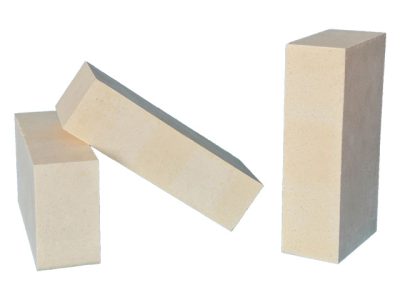

Yalıtım Tuğlaları

Yalıtım tuğlalarımızla fırınlarınızın ve ocaklarınızın enerji verimli olmasını sağlayın ve ısınma sürelerini kısaltın. Mükemmel ısı yalıtım özellikleri sunarlar ve yüksek sıcaklıklarda bile termal stabiliteyi korurlar..

Magnezya Tuğlaları

Magnezya bazlı tuğlalarımız yüksek sıcaklıktaki fırın astarları için idealdir, döner fırınlar, ve yakma fırınları. Yüksek ısıya karşı olağanüstü direnç sunarlar, kimyasal erozyon, ve termal şok.

Mullit Tuğlalar

Mullit tuğlalar mükemmel termal şok direnci sunar, düşük termal genleşme, ve yüksek sıcaklıklarda büyük dayanıklılık. Genellikle elektrik ve ısı yalıtımı uygulamalarında kullanılırlar..

Yüksek Alümina Tuğlalar

Yüksek alümina tuğlalarımız yüksek kaliteli boksitten yapılmıştır, ve yüksek sıcaklık uygulamaları için mükemmeldir. 1780°C’ye kadar sıcaklıklara dayanabilirler, aşınmaya ve yıpranmaya karşı dayanıklıdır, ve düşük ısı iletkenliğine sahip.

Silika Tuğlalar

Yüksek kaliteli silika tuğlalarımız fırın astarları için mükemmeldir, fırınlar, ve diğer yüksek sıcaklık uygulamaları. Son derece dayanıklıdırlar, korozyona dayanıklı, ve 1600°C'ye kadar sıcaklıklara dayanabilir.

Krom Tuğlalar

Yüksek saflıkta kromit cevherinden yapılmış, Krom tuğlalarımız erimiş metal uygulamaları için idealdir, dökümhaneler ve çelik fabrikalarda olduğu gibi. Çok aşınmaya dayanıklıdırlar, düşük gözenekliliğe sahip olmak, ve mükemmel termal stabilite sunar.

AZS Tuğlaları

AZS tuğlalarımız, yüksek dereceli hammaddelerin ve benzersiz dayanıklılığı sağlayan gelişmiş üretim süreçlerinin eşsiz bir karışımından yapılmıştır., esneklik ve termal şoka karşı direnç, erozyon ve kimyasal saldırı.

Kil tuğlaları

PER standart kil tuğlalar ve özel kil tuğlalar üretmektedir. Ürettiğimiz kil tuğlalar cam fırınlarına uygundur, seramik fırınlar, döner fırınlar ve diğer endüstriyel fırınlar. Standart kil tuğlaların çalışma sıcaklığı 1250°C -1350°C'dir..

Hafif Tuğlalar

PER refrakter tuğla üreticisi standart hafif tuğlalar veya özelleştirilmiş refrakter ateş tuğlaları sunmaktadır.. Ürünler hafif kil tuğlaları içerir, hafif silika tuğlaları, hafif mulit tuğlalar, hafif yalıtım tuğlaları, vesaire.

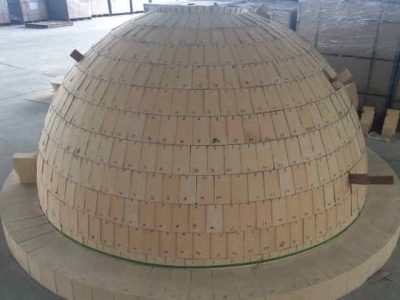

Fırın Ateş Tuğlası

Çeşitli alkalin refrakter tuğlalar sunuyoruz, asit refrakter tuğlalar, ve nötr refrakter tuğlalar. Ayrıca, Çeşitli fırın tuğlalarını talep üzerine özelleştirebiliriz.

Endülüs Tuğla

PER'in andalusit refrakter tuğlaları iyi derecede düşük ısı iletkenliğine sahiptir, Cüruflaşmaya ve sürünmeye karşı yüksek direnç. Sıcak yüksek fırında kullanılabilir, sıcak patlama kulesi, yüksek fırın ve diğer önemli parçalar.

Yangın tuğlaları nasıl paketlenmiştir?

Refrakter Moper Üretim Şirketi, refrakter tuğlaları ihraç etme konusunda uzun yıllardır deneyime sahiptir.:

Genel Fireproof tuğla ambalaj iki yöne ayrılmıştır: ahşap palet veya saman ipi.

1. Ahşap palet ambalajı genellikle 1m × 1m uzunluğunda ve genişliğindedir, Ve taban 15 cm, Peki refrakter tuğlalar ahşap palete nasıl yerleştirilir?

Örneğin, Standart tuğlanın boyutu 230 * 114 * 65mm, Katman başına dört gezi dikey 15 ile ilgili + yatay 4 = 64.

Kil tuğlalarının 3.4kg/bloğuna göre, On ila on iki katmanla yüklenebilir. Her palet, üst sınırına göre paketlenir 2.3 ton.

2. Örnek olarak standart tuğlaya saman halat ambalajı, genel olarak 6 Birlikte paketlenmiş parçalar.

Refrakter tuğla fiziksel kimyasal fonksiyon referansı

Firebrick’in temel kalite gereksinimleri, 38% (genellikle 42-47%) ve düşük demir ve düşük alkali metal içeriği, Bunlar kimyasal özelliklerine ait olmalıdır.

Ancak ateş tuğlalarının özellikleri gibi fiziksel özellikleri anlarken, Refrakter tuğlaların fiziksel ve kimyasal özelliklerinden bahsetmeyi ihmal etmeyin. Bu tür özellikler arasında şekilli refrakter tuğlalar, Kola fırınları için yüksek alümina yangın tuğlaları, vesaire. sahip olacak.

Ateşe dirençli tuğlalar, ferrosilikon alaşımının ve endüstriyel silikonun metalurjisi sırasında meydana gelen SIO2 ve Si gazlı durumun yoğunlaşmasıyla oluşan bir tür ultra ince silika toz malzemesi olduğundan oksijende hızlı oksijenasyon.

En başta, Fireproof tuğlaların görünümü gri ve beyaz bir tozdur, Refrakterlerle > 1600 ℃. Kapasitesi: 200~ 250kg/m3.

Saniye, Yangına dayanıklı tuğlaların hassasiyeti, yangına dayanıklı tuğlalar 1 Micron daha fazlasını oluşturdu 80%, kişi başına partikül boyutu 0.1 ~ 0.3 mikron, Özel yüzey alanı: 20 ~ 28m2 / G. Hassasiyeti ve belirli yüzey alanı yaklaşık 80 ~ 10100 Çeliklerin zamanları, Ve 50 ~ 70 uçuş külü. Hassasiyeti nispeten daha yüksek olacak.

Nihayet, Parçacık malzemesi durumu ve mineral faz yapısı, Kompozisyon sürecinde yangına dayanıklı tuğlalar, Yüzey çekiminin faydası ile faz değişimi süreci nedeniyle, kristal olmayan bir faz amorf yuvarlak küresel parçacıklar oluşturur. Ve yüzey tabakası oldukça kaygan, Bazıları, neşeli agregalar durumunda birden fazla yuvarlak küresel parçacık yapışır.

Çok bir tür volkanik kül nesnesidir, çok büyük spesifik yüzey alanı ve çok, çok yüksek aktivite. Yangın tuğlaları ile karıştırılmış malzeme, İnce küresel bir vücut yağlama etkisi oynayabilir.

Ateşe dayanıklı tuğlalar, yüksek sıcaklık yapı malzemeleri ve yapısal malzemeler olarak kullanılabilir.. Yüksek sıcaklıklarda çeşitli fiziksel ve kimyasal değişikliklere ve mekanik etkilere maruz kalan çeşitli ısıtma ekipmanlarının yanı sıra. Kil tuğlalar gibi, yüksek alümina tuğlaları, silikon tuğlalar, magnezyum tuğlaları, Silikon Mullit Tuğlalar, vesaire.

Yüksek alümina tuğlalar: Yüksek alümina refrakter tuğla 75% AL2O3 içeriği ve yüksek refrakterler. Asit ve alkali erozyona direnme yeteneğine sahiptir. Çimento fırını ateşleme bölgesinin yeri için uygundur.

Silisyum karbür tuğlalar: Yüksek sıcaklık direnci var, düşük termal genleşme, iyi aşınma direnci, ve iyi termal şok direnci, ve fırın soğutma kemerleri ve çıkışlar için uygundur.

Silika mullit tuğlaları: Hammadde boksit ve silikon karbürdür, baskı ve sinterleme ile yapılır. İyi termal şok direncine sahip geçiş bölgesi için uygundur, yüksek güç, ve iyi aşınma direnci.

Kil tuğlaları: Zayıf asidik refrakter bir malzemedir. İyi termal stabiliteye sahiptir ve sıcak hava fırını odası için uygundur.

Yangın tuğlalarının temel özellikleri

Refrakter başına daha fazlası var 20 Refrakter tuğla ve refrakter dökülebilir ürünler üretiminde yılların deneyimini. Zengin deneyimimiz, ürünlerimizin çok fazla refrakter malzeme fiyat avantajına ve kalite avantajına sahip olmasını sağlar:

1. Yangın tuğlalarının yumuşatma sıcaklığı

“Refrakterlik” Başvuru sürecinin üretiminde, yüksek sıcaklık derecesine dirençli olabilecek refrakter ürünleri ifade eder., ve eritilmiş işlev değil. Yangın tuğlası hidrolik pres, maliyeti etkili bir şekilde azaltabilir ve malzeme kaybından tasarruf edebilir.

Özellikle bitmiş ürün oranında büyük ilerleme, Refrakter bir fabrikayı üretim verimliliğini iyileştirmekle kalmaz, aynı zamanda işçilik maliyetlerinden de büyük ölçüde tasarruf edebilir.

The “oda sıcaklığı direnci zhuang mukavemeti” Ateşli olmayan refrakter malzemelere sahip ateşli olmayan ısıya dayanıklı yangın tuğla ürünlerinin kullanımının ana kalite göstergelerinden biridir..

2. Refrakter tuğla basınç direnci gücü

Yangın dereceli ürünlerin küçük gözenekliliği, iyi bir yoğunluğu gösteren, Ve tuğlanın kalitesi iyi.

Görünen gözeneklilik, gözeneklerin hacminin oranıdır (Yani, kavitasyonun başlatılması) Atmosfer içindeki toplam yangına dayanıklı ürün hacmine.

Firebrick ürünlerinin iki basınç gücü kavramı vardır.

Bir denir “oda sıcaklığı basınç dayanımı”, kapalı laboratuvarda nihai basınç gerilim mukavemeti olarak tanımlanır, yok edilmeden dayanabilecek numunenin birim alanına göre.

İkincisi denir “yüksek sıcaklıkta basınç dayanımı”, Refrakter bir ürün örneğinin, belirli bir yüksek sıcaklığa ateş ederek yok edilmeden birim kesit alanına dayanabileceği nihai basınç stresi olarak tanımlanır.. Refrakter malzemede, Bu iki tür gözeneklilik yüzde olarak ifade edilir.

3. Ateş Refrakter Refrakter Tuğlalar

Dört sütunlu bir hidrolik sistem kullanımı, Tuğla hava kuvvetleri ortalaması, basınç, refrakter endüstrisinde yaygın olarak kullanılan.

Özellikle büyük refrakterler ve özel refrakter üretim alanı, aynı zamanda önemli bir rol oynayın.

Firebrick Press'in kalıbını değiştirerek, ve maddi oranlar, Çeşitli özel refrakter malzemelerin üretimi nispeten kolay hale gelir.

Ekipman yatırımındaki artışa dayanarak, Refrakter tuğla hidrolik presleri çok amaçlı bir makine elde edebilir, Çok amaçlı bir makine.

Başka bir denir “gerçek gözeneklilik”, yani, refrakter ürünlerdeki tüm gözeneklerin hacmi (Açık ve kapalı gözenekler dahil) oranın toplam hacmine.

“Normal Sıcaklık Basınç Gücü” Genel refrakter ürünler için, fırın malzemesi üzerindeki etkisinin bir ölçüsüdür, giymek, ve sıvı cüruf yıkama önemli göstergelerden birine direnebilir.

4. Gözeneklilik

“Yüksek sıcaklık yükü yumuşatma noktası” Üretim sürecinde satılık ürünlere karşı yangına dayanıklı tuğlaları ifade eder, Sadece yüksek sıcaklığa direnmek için değil, Ve cürufa direnmek, Çeşitli metal veya malzeme çözümleri, veya yıkama korozyonunun işlenmesi, aside dirençli tuğlalar ve fırın gövdesinin yapısal kısımlarının basıncına dayanır. Aşırı sınırın yukarıdaki işlevini denemek “Yüksek sıcaklık yükü yumuşatma noktası”.

Refrakter ürünlerinde birkaç profesyonel fırın da var, gözeneklilik gereksinimleri çok küçük olmamalı, Hızlı soğuk algınlığı ve ısıya karşı direnç işlevine sahip olmak.

Refrakter Grubu Hakkında

PER Refrakter Şirketi Xinmi şehrinde bulunuyor, Henan Eyaleti, Çin'deki refrakter malzemelerin memleketi. Şirketimiz R'yi entegre eden teknoloji tabanlı bir refrakter kuruluştur.&D, üretme, satış, ve teknik servis. Bölgedeki zengin kaynaklar ve mükemmel kalite, refrakter malzemelerin üretimi için benzersiz üstün koşullar sağlamaktadır.. Satış için ana itfaiyemiz refrakter kil tuğlalar, yüksek alümina tuğlaları, Silika Ateş Tuğlaları, magnezyum refrakter tuğlalar, müllit tuğlalar, Yalıtım Ateş Tuğlaları, ve diğer yüksek sıcaklığa dayanıklı ürünler.

PER en önemli şeyi düşünüyor, Her ürünü ciddiye almaya ve her müşteriyi içtenlikle karşılamaya inanıyoruz. Tüm müşterilerimize hızlı ve kaliteli sonuçlar sunmak. PER Refrakter, en güvenilir refrakter üreticiniz ve güvenilir ortağınız olacak.

PER refrakter şirketi yeşilin üretim üssüdür, enerji tasarrufu, ve çevre dostu yeni refrakter malzemeler. Firmamız ISO9001'i geçti:2008 uluslararası kalite sistem sertifikası ve GB/T24001-2004 / ISO14001:2004 çevre yönetim sistemi belgelendirmesi, kurumsal kalite kontrol ajansı sertifikası. Ürünlerimiz birden fazla ülkede iyi satılmaktadır 20 dünyanın her yerindeki ülkeler. Tercih edilen onlar refrakter ürünler metalurji için, demir dışı, petrokimya, bardak, seramik, ve diğer refrakter endüstrileri.