Smelting of Pure Steel

With the increase in the purity of steel and a variety of properties, accelerating the development of high-purity steel, its production increased year by year. Previously, the development of high-purity steel was mainly structural steel with good mechanical properties, such as plate, wire, bar, etc. And in recent years, the development of cold rolled materials, surface treatment materials, and stainless steel, from production to quality have been greatly developed. In this paper, the smelting of pure steel is used in refractory materials to do a brief description.

Steel purification technology is a comprehensive technology, steelmaking in all aspects of the measures to be taken to remove inclusions, smelting high purity steel process:

Iron pretreatment → converter → secondary refining → continuous casting

The iron pretreatment is mainly off Si, P, S, converter is mainly off C., the second refining is to minimize the various impurities, and continuous casting is to promote the separation of impurities upward.

Refractories at high temperatures in direct contact with the molten metal, should not only adapt to the increasingly harsh smelting conditions, such as high temperatures, long processing time, stirring, vacuum, etc., but also consider the recontamination of molten steel, so how to choose the right refractory materials, the development of new refractory materials is an important research topic in the future.

Iron pretreatment technology for melting high-purity steel, is more and more important, in this process if you can fully remove P and S, the later process can be reduced to the limit of P, S.

When there is no iron pretreatment process, the lining of torpedo-shaped iron tank cars is mainly made of high aluminum refractory materials. Due to its high melt loss and poor durability, it was changed to Al2O3-SiO2-C and MgO-C refractories. In the future, refractories with heat insulation and prevention of temperature drop should be developed. Refractories that can work with slagging agents and unshaped refractories.

Castables

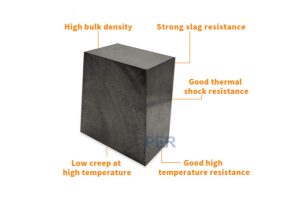

Converter is mainly de-C, due to the high temperature of steel, refractory load increases, harsh environment, and the use of refractory materials more than 90% for MgO-C brick. Its thermal strength, heat shock resistance, and excellent slag resistance, but poor acid resistance, so the ingredients should be selected low B2O3, crystallization, high CaO/SiO2 ratio of MgO sand, low ash micro-fine graphite and additive metal Al, Mg, Si, Al-Mg and other additives.

Ladle (secondary refining) according to the requirements of high purity of steel, with a variety of functions, such as degassing (H, N), off O, C, P, S, control of inclusions morphology, adjusting the composition and temperature regulation.

Refractory materials used to use the leaves are wax stone brick, its SiO2 content is high, and not suitable for smelting high-purity steel. Now mainly with less SiO2 content, resistance to steel, and slag erosion of high aluminum, magnesium, and spinel alkaline refractories. With the high purity of steel, refractory materials from acidic, neutral to alkaline change.

The RH degassing process has been used as the main secondary refining equipment in recent years. Previously, mainly with Al2O3 refractories, now mainly with MgO-Cr2O3, and in the future will be MgO-C and MgO-Cr2O3 with the use of MgO-Cr2O3-based.

Magnesium Shaped Refractories

70% of the world’s stainless steel is produced by the AOD refining furnace, the use of Refractories are mainly magnesium-chromium bricks, magnesium-calcium bricks, dolomite bricks, dolomite carbon bricks, and magnesium dolomite bricks.

For the converter refining stainless steel, the lining is mainly used for non-burning MgO-CaO-C bricks, because for MgO-C bricks, above 1600 ℃, the reaction occurs: MgO-C → Mg (g) + CO, CaO is more stable than MgO at high temperatures, which prevents the deterioration of the brick organization at high temperatures. In addition, CaO reacts with SiO2 in the slag to generate high melting point compounds, preventing further penetration of the slag.

According to Japanese reports, with magnesium chromium brick and magnesium dolomite brick masonry 55 tons of AOD furnace, without special repair, direct combination of magnesium chromium brick life for an average of 50 furnaces, magnesium dolomite brick life for an average of 70 furnaces.

Germany bought a metallurgy company 15 tons AOD furnace with direct bonded dolomite brick masonry, lining thickness of 350mm, life of 139 times.

Due to the different conditions of use, AOD furnace refractory unit consumption is between 10 ~ 20 kg/ton of steel, and Japan’s AOD furnace refractory minimum unit consumption of 7.7 kg/ton of steel.

China’s refining furnace in the use of MgO-CaO system refractories on the slower development. So far, only a few steel mills use it. It is believed that with the increase in pure steel requirements, MgO-CaO refractories will be widely used in the refining furnace.

Smelt high Cr, low C, N stainless steel, mainly with VOD refining furnace, the requirements of refractories with good resistance to slag and thermal shock resistance, the use of magnesium-calcium bricks and non-burning magnesium-calcium bricks, magnesium spinel castables, and magnesium-calcium castables.

To improve the purity of steel must reduce the oxide system inclusions, that is, in addition to O, CaO quality and MgO-CaO quality refractory materials to reduce the steel [O] is effective. Therefore, continuous casting intermediate ladle lining refractories mainly with alkaline, especially in recent years began to gradually use MgO-CaO quality.

Immersed in the mouth of the water often have Al2O3 attached, these attached Al2O3 irregularly detached into the steel resulting in inclusions, which must be solved Al2O3 attached to the clogging problem. The solution is to improve the structure and material of the immersed water outlet. Continuous casting is the final process to determine the quality of steel, if the refractory material is caused by contamination of steel, it will become a permanent inclusions, so it is important to prevent the steel re-oxidation and inclusions uplift technology.

Currently, in the smelting of high purity steel process, more and more attention is paid to the refractory material is MgO-CaO system refractory materials.

MgO-CaO system refractories in addition to good thermal shock stability, high-temperature chemical stability, and slag resistance.

This characteristic of MgO-CaO refractories makes them ideal lining materials for refining furnaces, so much so that the world has seen a boom in the application of MgO-CaO refractories in refining furnaces.

Dolomite is the only furnace lining material used in the Nordic countries. It is foreseeable that aluminum silicate or even high-alumina barrel lining will gradually disappear, and this evolutionary process will favor the use of MgO-CaO refractories with excellent performance.

With the increase in high-purity steel production, the increase in molten steel temperature, the processing time is extended, stirring intensity increases, etc., so that the refractory load increases. Since the refractory material produces inclusions by interacting with the molten steel, the high-purity steel purification technology and the refractory material require strict quality and performance at the same time. Therefore, we will continue to develop refractory materials and technologies suitable for smelting pure steel.